3431

IoT Predictive Maintenance: A Guide to Industry 4.0’s Leading Use Case

18 Sep, 2020

10 min read

3431

18 Sep, 2020

10 min read

Industry 4.0 and IoT together have brought a digital lean in manufacturing, leading to enhanced efficiency, process improvement, and increased automation. While the applications can derive many benefits from IIoT, predictive maintenance is the leading use case for manufacturers, factory managers, and asset managers.

By using sensors and intelligence, companies can spot patterns in asset condition and performance, and predict its failure or maintenance span. Real-time alerts and foresight eliminate unplanned downtime, reduce service costs, and improve production throughput.

This means predictive maintenance can solve the problems, the solutions of which we once only imagined. Intelligence-based predictive maintenance is becoming the industry essential but before knowing how and its future, let’s learn about its roots and how it evolved.

Remember the time when your machine broke and you went out to fix it? That’s reactive maintenance, the first generation of maintenance that took place after the failure occurred. To get rid of these last-minute checks and heavy expenses, came preventive maintenance where you would maintain your machines and equipment on a fixed schedule. It’s like taking your vehicle for a routine maintenance check and oil change every 12 months. However, that wasn’t sufficient because sometimes your machine broke down before the set regular service, or sometimes the time period between two scheduled services was too much.

With time and technology, you got smarter and started understanding the condition of assets by taking measurements with vibration monitors or ultrasonic devices. You created a predictive maintenance capability, manually.

This worked but it required an operator going onsite, taking readings, capturing data then creating spreadsheets and predicting maintenance based on the analysis. It also required informing the system engineer and staff about it. The result helped a great deal but the execution was exhausting. It was done on an ad-hoc basis. And then IoT came up, simplifying the process with real-time monitoring, sending data to algorithms and detecting the condition of assets, and predicting maintenance based on it.

Predictive maintenance using IoT enables industries to predict machine failures before the actual asset breakdown occurs. The main objectives of IoT based predictive maintenance are:

Manufacturers can read the production data such as how much load the machine can handle or what number of goods should be used, if the raw materials are in good condition, etc. and improve the overall efficiency. Proper proportion and quality help in maintaining production and asset health.

By analyzing future failures, analysts can take precautionary measures at the right time. This reduces overall maintenance costs and increases asset lifespan.

As all the data and process is carried out using technology and algorithms, it simplifies the overall business process and reduces human intervention.

Predictive maintenance is usually associated with keeping a check on the ‘health’ of the asset and predicting the corrective measures. Using sensors, data is collected and then the system engineer visits the plant to collect data using a data collector. However, this once a month predictive maintenance check is not viable as it comes with several limitations such as:

In the traditional approach, data is collected every 30 to 90 days. If a failure is detected after the data is collected for the month, it remains undetected until the next data collection duration. This leaves assets prone to failure and may result in dealing with the loss.

Technicians may not install the sensors accurately and consistently. This may result in faulty and inaccurate data.

While collecting data, it is necessary that machines remain in the same operating condition. If a system engineer sees a spike in the data level, they may mistake it for a fault in the machine. However, it may be due to the increased load.

Sometimes, it’s impossible for a human to access machinery due to technicalities or location. This may end up not collecting data on that machine in real-time.

All the data is accessed manually, which is not in real-time. And then predicting the maintenance of thousands of machines based on those analyses can result in inaccurate decisions.

Till recently, many industries kept using the traditional approach because continuous monitoring and IoT based Predictive maintenance was expensive. But not anymore!

IoT based predictive maintenance ensures continuous monitoring of the assets in real-time. It is revolutionizing due to technological trends:

With the use of cellular and wireless connectivity, it is easy to enable sensors to collect and transmit asset data. Sensors no longer need to be wired thus reducing costs and transmitting data seamlessly.

With mobile phones, the price of sensors is decreasing. Miniaturized low-cost MEM sensors are readily available and affordable.

Cloud computing allows the on-demand availability of the data and resources. Using it, industries can start small and readily expand in the meantime.

AI is turning the business phase. Monitoring sensors and collecting data in real-time manually is impossible. But intelligent computers have made it possible. AI can be the assistant of the analysts.

All these trends are paving the way to technological advancements, bringing some value when used. However, when combined together, they can automate a complete industrial process.

So how does predictive maintenance using IoT work? At the front-end, it delivers the output gathered by collecting several technological trends such as big data, cloud computing, edge computing, machine learning, and connectivity sensors. At the backend, the IoT solution is built using core products that would carry out specific tasks. These products include sensors, wired and wireless solutions, antennas, batteries, and small connectors, and passive components that provide low-power connectivity. Before assembling, they are tested and experimented in various conditions so as to withstand adverse conditions within industrial environments.

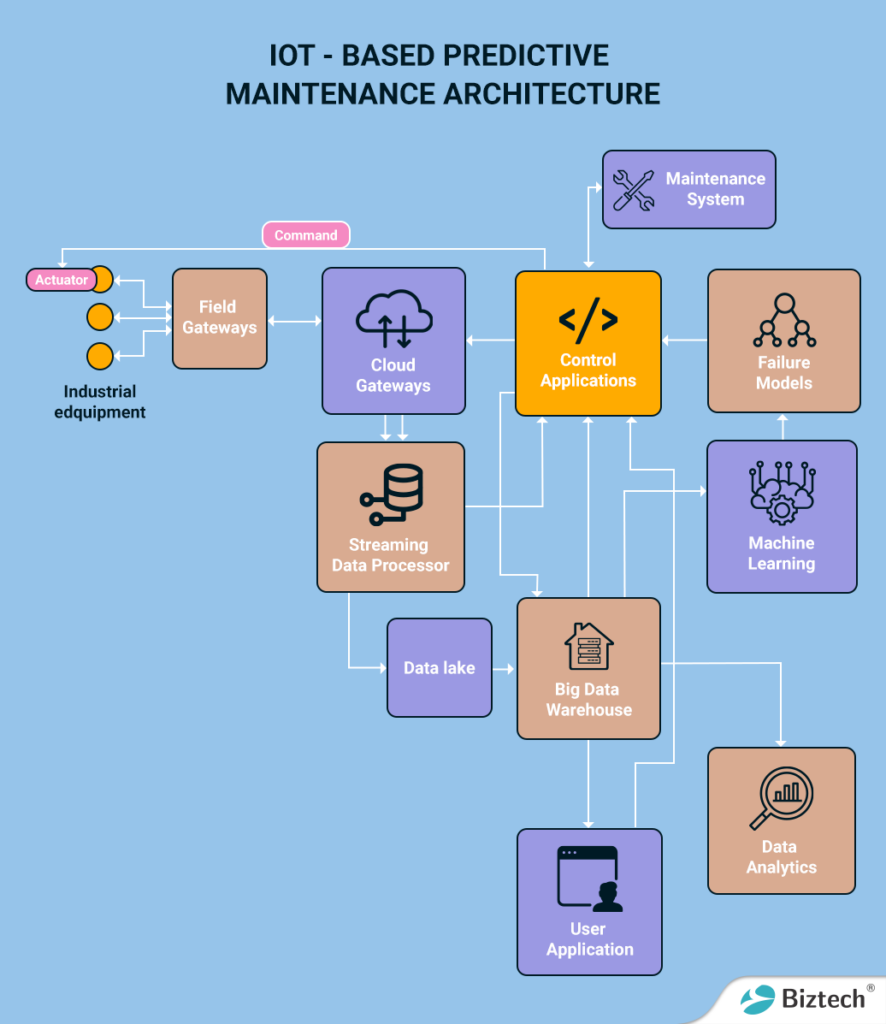

Once experimented, assets such as actuators, motors, and drives get equipped with sensors that gather the data, filter it through gateways*, and then push it on the cloud for processing.

* Field gateways (physical devices that filter and preprocess the data) and cloud gateway (safe data transmission and connectivity via various protocols that allow connecting multiple field gateways).

Once sensor data enters the cloud, it is then repacked by the streaming data processor so that it can stream in a continuous flow to a data lake for filtration. Data lake stores the data gathered by sensors. The data is raw and can be erroneous or contain irrelevant items.

Here, the data is stored as a number of sets of sensor readings measured at the corresponding time. When the data is needed for insights, it’s loaded to a big data warehouse, where it is structured into more meaningful information based on different parameters such as temperature, voltage, or vibration. Once the structured data is prepared, it is analyzed with machine learning (ML) algorithms to identify any anomalies or hidden data patterns. The recognized data patterns are then instigated into predictive models that are built and trained over time, to deliver accuracy and value.

To ensure that the right data is collected and the right datasets are analyzed, predictive models are regularly updated and tested for accuracy. If the result differs from the expected one, the models are revised, retrained, and tested again until they function properly. Moreover, usage history data, service information, model specifics can be used to improve the asset’s predictive outcomes.

But before getting to the ML, it’s good to carry out exploratory analytics that helps in selecting the best-fit machine learning algorithm by assessing technical assumptions.

After all, machine learning software can recognize patterns, identify abnormal behavior in the context of variable industrial settings, and understand long term-trends and avoid undesired events.

IoT Predictive maintenance can be applied to all the industries where assets produce data and require maintenance and fine-tuning of its parameters and components. Both discrete industries such as consumer packaged goods, automotive, electronics, textiles, aerospace, and process industries like food and beverage, chemicals, oil and gas, pharma can now accurately interpret data and maintenance tasks with predictive maintenance. Below, I have listed a few industries where predictive maintenance is already growing traction. Let’s check it out.

Check out the Ovivo case study

In the next 10-20 years, half of your engineers will retire, creating workflow shortage. In that case, digitalization and predictive maintenance will deal with half of the work, reducing your stress. The other benefits of IoT Predictive Maintenance are:

When it comes to assets, there are many hidden costs and expensive maintenance involved. IoT based predictive maintenance reduces the overall cost by detecting and avoiding failures. It collects real-time data from multiple sources such as IoT devices, sensors, and other equipment to make accurate predictions about asset health, functioning, failure rate, future maintenance, etc. Overall, maintenance time reduces by 20-50 percent and costs by 5-10 percent. Thus, saving the manufacturer and customers’ time as well as money.

Maintenance can be planned based on the insights generated by analytics software. It will further reduce unnecessary maintenance by discovering issues ahead of failure, thereby, increasing productivity and efficiency.

Predictive maintenance dashboards, maintenance schedules, technician services before parts need replacement, etc. services help manufacturers to analyze industrial predictive maintenance and provide customers with accurate data and opportunity for generating multiple revenue streams and business growth.

IoT based predictive maintenance detects the overall asset condition and automates the processing. It generates automated alerts when parts need to be replaced or a maintenance action is required by the machine engineer, thereby, boosting customer satisfaction.

IoT based predictive maintenance increases company branding by automating the business and adding value to customer satisfaction. This enables the company to stand alone from the competition and provide continuous benefit in-market.

Assets in hazardous or confined environments often have a higher risk of danger and injuries. IoT based predictive maintenance enables human officers to inspect the asset environment remotely without risking their life.

The future that would replace preventive maintenance by IoT predictive maintenance is here. All the tedious manual tasks would soon be automated and human actions would only be required only when predictive technologies indicate failing health. With clear advantages, predictive maintenance using IoT is poised to transform maintenance forever. If you’re into a business that requires regular asset management, use IoT for predictive maintenance. To know more about IoT, reach us at sales@biztechcs.com.

Development

Laravel

128

By Devik Gondaliya

22 Aug, 2024

Development

Devops

125

By Biztech

20 Aug, 2024

Javascript

248

By Devik Gondaliya

13 Aug, 2024